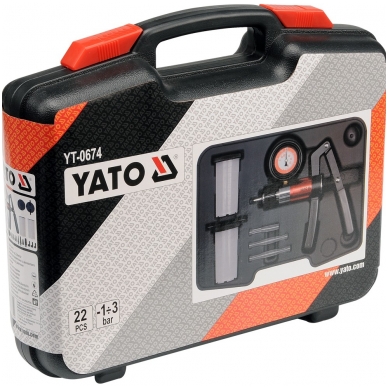

Vakuumo ir slėgio matuoklis stabdžių skysčio nuorinimui (dvigubo veikimo)

Vakuumo ir slėgio matuoklis stabdžių skysčio nuorinimui (dvigubo veikimo)

Kodas: YT-06745890 €Lizingo skaičiuoklės- sbl

- esto

GamintojasYATO-

Vakuumo ir slėgio matuoklis stabdžių skysčio nuorinimui (dvigubo veikimo) YATO

Vacuum pump is a multifunctional device used to diagnose systems in cars and technology that operate on pressure or under pressure. Equipped with accessories for use in almost any engine or system.

The YT-0674 is equipped with a switch which, depending on the position, allows to produce vacuum or pressure.

Moving the switch towards the outlet of the pump will cause negative pressure to be generated during pumping. The switch to the handle will cause pressure to be generated during pumping.Measuring range: -1 to 3 bar

Destination / Application

With the pump you can perform diagnostics, among others. The following systems and systems:Computerized engine control equipment:

- barometric pressure sensor (BARO)

- PVC system

- exhaust gas recirculation system (EGR)

- thick-layer pressure sensors (MAP)Ignition control devices:

- underpressure ignition ahead

- delay valve: SDV, RCVBrake system:

- classic brakes

ABS brakes

- pneumatic brakes

- Brake cables

- brake servoOther systems:

- air conditioning

- Cruise control

- fuel tank and fuel system

- vacuum door closing system

How to use

Diagnosis of exhaust gas recirculation (EGR)

The EGR valve is an example of a vacuum operated valve. In the absence of negative pressure the valve is closed and the exhaust fumes do not escape from the valve. When the vacuum is applied to the valve, it is opened to allow recirculation of the exhaust gas.Diagnosis of thick-walled pressure sensors (MAP)

• Assemble the pump and tank system as in the case of bleeding of the brake caliper and then connect it to the vacuum connection of the sensor.

• Press the pump lever until the tip shows -0.5 bar. Stop pumping and watch the hint, it should be fixed. If the pointer moves, it means MAP sensor damage.

• During operation, the MAP sensor sends feedback signals to the control computer. The signal has a frequency between 85 Hz and 160 Hz depending on the vacuum level. Frequency meter is required to measure the frequency, it must be connected according to the instructions of the sensor and the meter.Venting the brake calipers.

• Make sure that the brake fluid reservoir is filled with fluid to the nominal volume.

• Bleed out in the following order:

- the master cylinder if equipped with a vent valve

- brake clamps in the order from the nearest to the master cylinder to the furthest distance

• Connect the short flexible hose to the connector located on the bottom of the pump tank cover.

• Close the pump reservoir using the lid.

• Connect long flexible hoses to the cover connectors. The end of one of the long hoses is connected to the pump and the other to the bleed valve of the brake caliper. Use an adapter if needed.

• Press the pump lever 10 - 15 times to generate a vacuum in the pump reservoir.

• Unscrew the bleed valve by 1/4 - 1/2 turn, so that the pump tank fills up to about 5 cm. Tighten the vent valve.

• Disconnect the pump hose from the bleed valve, the bleed procedure is completed.

• Before performing the bleed procedure in the next clamp, drain the pump reservoir from the brake fluid and make up the brake fluid level in the brake system to the nominal level.

Gross Weight (kg) 2.0000

Number of items 22